Products

Axial Pyro Torch Fishing ToolThe Axial Pyro Torch is the best kept secret in the oilfield. MCR engineers have recognized the flexibility, and increasing number of applications, for the APT. Well operators, service companies, and in particular, fishing companies will be happy to know there is a solution for metallic debris stuck in the wellbore. The Axial Pyro Torch is designed to be run down on top of the debris and burn thru it. The APT by MCR Oil Tools can be deployed on slickline, wireline , coiled tubing and other tool   Perforating Torch CutterMCR’s Perforating Torch Cutter™ tool provides the industry with a safe, efficient and reliable pipe punching alternative to explosives. MCR’s Perforating Torch Cutter tool effectively perforates coiled tubing, tubing, casing and drill pipe without the use of restrictive technologies. When running a job that requires adequate flow into the annulus, explosive perforators and punchers are unreliable in many configurations at producing a consistent or sufficient hole in pipe.   Radial Cutting TorchMCR’s Radial Cutting Torch™ tool is the safest and most efficient wireline and slickline pipe cutting device available in the industry. Based on patented cutting technology, MCR’s Radial Cutting Torch tool, or RCT™ tool, is used to sever tubing, casing, drill pipe, and coiled tubing without the use of explosives, making it one of the safest pipe cutting tools on the market. Click to read more...

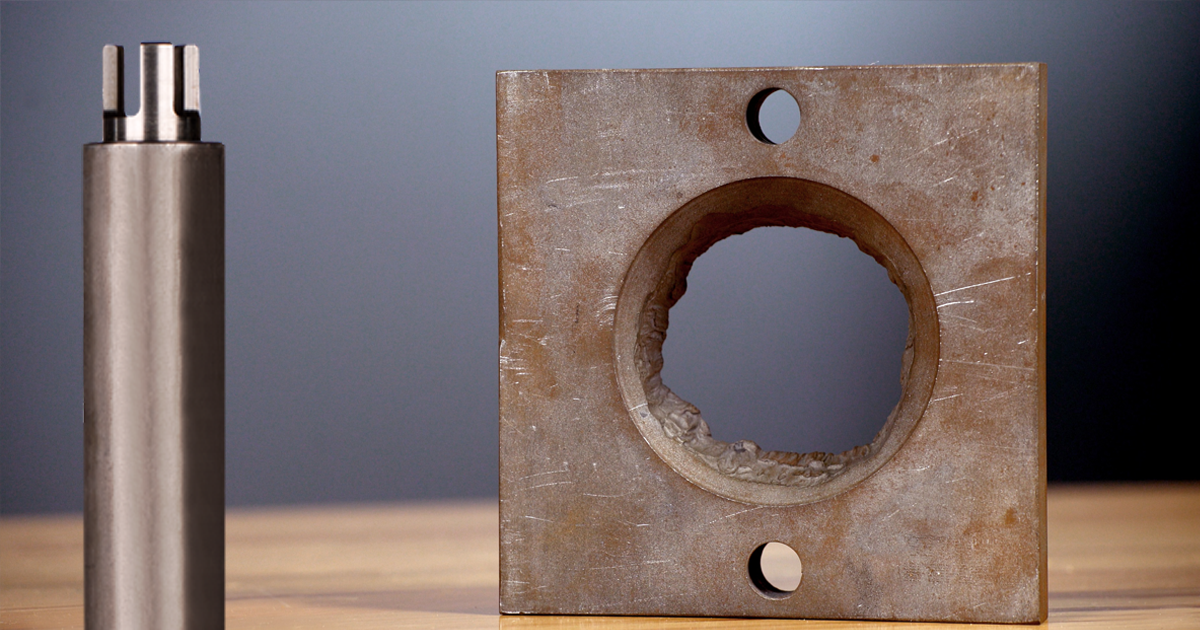

001_thumb.png)  Generator Safety SleeveWhen operations require "electric before ballistic" tool string handling, the Generator Safety Sleeve is required equipment. By design, the Generator Safety Sleeve will safely dissipate all Thermal Generator energy if subjected to an unintentional Thermal Generator discharge. Convenient to fasten and remote during tool string assembly, the Generator Safety Sleeve is the valuable Safety Tool for field personnel.   Electro-Mechanical AnchorMCR Oil Tools Electro Mechanical Anchor is an electric line or slickline deployed anchoring device intended for use with MCR’s systems for pipe recovery operations in the oilfield. With outside diameters (retracted) of 1-1/2”, 1-3/4“ and 2-1/2”, EMA’s effectively anchor tools for cutting tubulars from 2-3/8” to 7-5/8”. Anchor arm material and design allow for fixation within ALL tubular materials covered by MCR system specifications, e.g. Monel®, Hastelloy®, Inconel®, Chrome, and plastic coated   Fire Panel FilterMCR’s Fire Panel Filter provides filtered DC power to ensure firing system functionality when used with inferior firing systems and clean DC power to operate electronic equipment such as MCR’s Electro-Mechanical Anchor (EMA). Each Fire Panel Filter (FPF) reduces “dirty” output from a DC source and filters the ripple. The FPF has a maximum operating voltage of 500V with a 5 Amp fuse limitation.   Check Fire PanelMCR’s CheckFire Panel system is both a firing system competency tool and an effective training aid for service providers. The CheckFire Panel ensures adequacy of your firing/logging system before entering the well. The panel, for use in conjunction with the Electro-Mechanical Anchor (EMA) and all MCR Thermal Generator™ ( THG™) activator components, can indicate if a wireline flaw or firing system failure exists while simulating downhole power threshold requirements. Click to   Remote Firing MechanismMCR’s Remote Firing Mechanism is a reliable activating system developed specifically for the MCR range of products. Designed and field proven with safety, versatility, and serviceability at its core, the Remote Firing Mechanism can be run on slickline, coiled tubing or drill pipe, and as a pressure firing system, to activate all MCR pipe cutting, MCR perforating and MCR setting tool systems.   Perforating Pyro TorchMCR’s Perforating Pyro Torch® tools offer high temperature deployability for specialized perforating services. Ranging in O.D. sizes from 2-1/2” to 3-3/8”, the PPT tool is a highly versatile addition to pipe and completion casing perforating process. Available as two or four-port systems, the PPT tool can be initiated on E-line, slickline, coiled tubing and pipe using MCR’s Remote Firing Mechanism (RFM).   StabiLocThe StabiLoc Anchoring System eliminates the concerns about tool movement caused by insufficent circulation, prventing the setbacks of failed pipe recovery operation, With its wide operation range and seamless integration with MCR's Radial Cutting Torch technology, StabiLoc facilitates efficent pipe recovery operation in a wide range of pipe sizes.   Specialized & Custom Solutions

|

|